This website uses cookies to improve your user experience. By continuing to surf, you agree with our Cookie and Privacy Policy. Accept

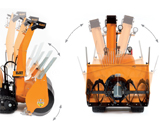

Snowbob 9018T

Endowing its Snowbob 9018T with power, speed, simplicity and comfort as the most important design criteria, ELIET has created a compact, powerful, high-performance machine capable of dealing with the most daunting tasks of snow clearing while maintaining a total focus on achieving the desired results.

225° VARIABLE BLOW CHUTE

The position of the discharge chute is electrically controlled and is located on the joystick for ready access. Within a rotation range of 225°, the operator can easily and safely fix the direction in which he wishes to throw the snow.

THE RED BUTTON

When, during the snow-clearing operation, one wants to go into reverse, it is recommended that the auger be lifted up. In order that this may be do done quickly and efficiently, ELIET has placed a red pushbutton on the back of the joystick which can be controlled with the index finger when moving in reverse. A significant advantage is that the operator can himself determine how high he wants to lift the snow clearing head, which can save time when, immediately following, the auger needs to be lowered again to continue clearing the snow.

LEFT HAND SIDE CONTROL

In the design of the instrument control dash board, ELIET has given a control function to the operator's left hand, which normally rests passively on the emergency (safety) lever. A small electrical joystick is positioned in such a way that it can be activated by the left thumb only. It serves to control the position of the snow clearing head. By involving the left hand, the operator can in essence control all of the fundamental components of the machine without having to move his hands away from their normal positions.

SNOW CLEARING HEAD CONTROL

The Snowbob's auger has an operational width of 90 cm and a clearing height of 62 cm. In cooperation with Parker, an electro-hydraulic linear actuator was developed whereby the snow clearing head can be lifted from -30 mm to +200 mm. Moving the snow clearing head from its nethermost to its uppermost position takes less than 5 seconds. The same actuator is used to tilt the auger sideways over an angle of 18° to the left or to the right.

ELIET HOT SPOT

When the mercury dips beneath the freezing point, and there is furthermore a biting wind-chill that makes it even colder, one of the significant assets of the Snowbob proves its full worth and value. The Snowbob has been provided with a operator heating system : ELIET Hot SpotTM

The motor of the machine is completely built into the housing. The cool air that keeps the motor and the transmission at the optimal operating temperature is likewise being redirected inside the machine so that the now warmed air is channelled into the operator's direction. Via a large grating at the rear of the machine, this warm air is blown onto his lower body, while a small grating above and at the side of the control dash board also directs this flow of warm air onto his hands. Likewise, the handles of the machines are warmed by the same hot air flow.

Professional operators that have to use the machine on a daily basis are very appreciative of this extra touch.

SNOW TRACKS

Just as tires are of the greatest importance to the performance of a racing car, so caterpillar tracks also contribute to the efficient performance of a snow blower. ELIET has selected top-quality Bridgestone tracks in its search for all-round excellence. The low-temperature rubber tracks, specially developed for operations in snow conditions, consist of a specially adapted rubber compound that comes with a special pattern to ensure optimal grip on the ground. The track has a cast-iron core that ensures excellent surface stability.

In order to operate efficiently and effectively, the machine needs to maintain an optimal grip when cutting into the snow. To this end, weight distribution is important, but essential is the contact area with the snow. The Snowbob is fitted with 200 mm-wide caterpillar tracks that cover a ground-contact area of 700 mm.

BALANCING TACK ROLLER

The ELIET Snowbob is supporterd by two solid rollers with balancing suspension located at the inner the tread of each track. This offers the advantage that the tread readily adjusts itself to the uneven surfaces that a machine frequently has to negotiate. As the rollers pose on the outer edge of the treads, the cross stability of the track is further enhanced. Maximum contact with the surface is thus assured, giving the snow blower optimal stability and traction. The balancing rollers have been robustly built and operate on sealed dust-free ball bearings protected by extra steel shields.

THE AUGER UNIT

When you look at the auger unit, you see sturdy reliability. The serrated auger has an aggressive set of teeth to resolutely bite its way into and through even frozen snow and ice. ELIET opted for 6 mm Hardox steel that turns the auger unit practically impervious to wear and tear even under the most challenging conditions. Inside its housing, the auger is supported by solid cast-iron bearing flanges provided with grease nipples.

1.Auger protection

1.1 Armour plating

The transmission gearbox has been provided with a solid protective armour-cover to ensure increased protection in case one encounters a hidden obstacle. The wedge shape of this armour ensures less resistance and better guidance of the snow towards the suction impeller.

1.2 Friction clutch

The replacement of shearing bolts is no longer a problem with the ELIET Snowbob. ELIET protects the auger by means of a friction disk clutch. When the auger is obstructed by a stone, for instance, the friction coupling slips through. In such an instance, it suffices to remove the obstruction to get going again. The torque setting to slip is furthermore easy to adjust.

EASY MAINTENANCE

Aside from a machine's operating reliability, it is equally important for the operator to be able to service his machine as rapidly as possible and with the least possible effort. Just as it is the case with racing cars, the side doors on the Snowbob open upwards and thus provide easy access for the maintenance of all machine parts such as the motor, belts, hydraulic filters, and others.

PTO DRIVE SHAFT

The moveable snow clearing head is powered by a telescopic joint drive shaft transmission. This offers the significant advantage that the cutter head can quickly be taken apart for maintenance. In addition, other attachments can be mounted and powered on the multi-functional support system.

-1.jpg)